New cost-effective solutions provide increased reliability, faster sampling rates and more accurate data

During the past six months, Probe has introduced new patented sensors and tools that dramatically improve data logging efficiency and accuracy.

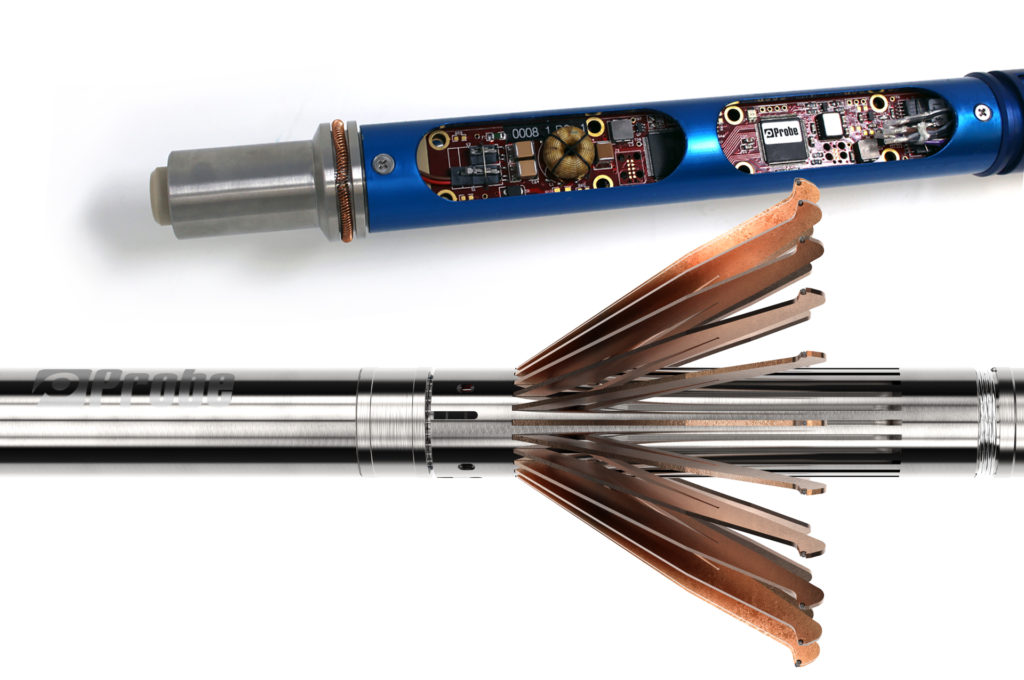

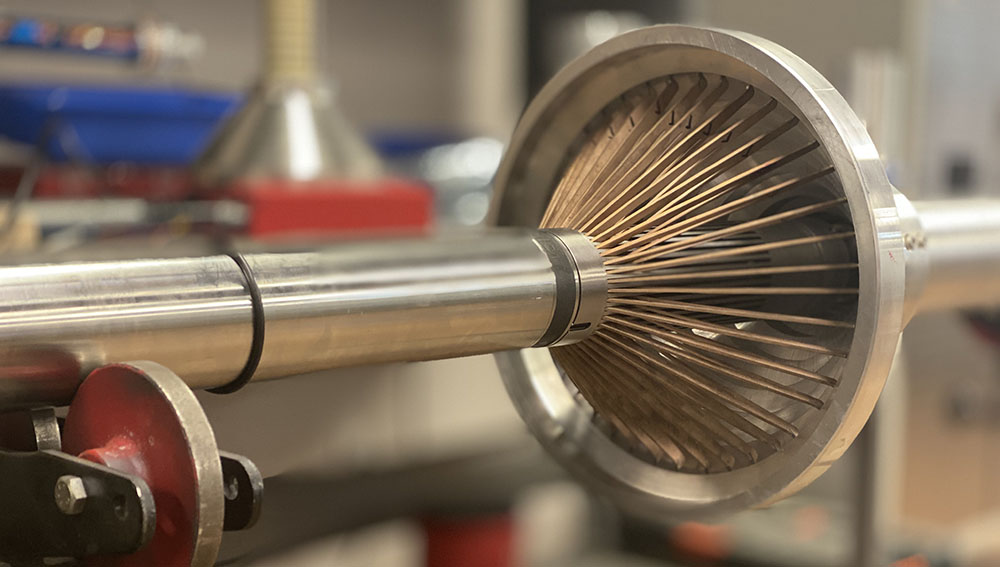

“We are absolutely driven by market demand for faster, more cost-effective solutions to log accurate data, so we set out to deliver that by innovating traditional logging technologies,” said Federico Casavantes, CEO of Probe. “For example, our new ProMAC™ Series of multi-arm caliper tools are fully combinable with all Probe HD Platform tools, and operate in Surface Readout or Memory modes. There are multiple improvements that increase reliability, maintainability and accuracy. One such improvement, for example, is that the tool’s sensors’ outstanding linearity and stability has allowed us to reduce calibration time to half a day. Consequently, our customers are able to increase asset utilization by minimizing downtime. It also means that electronics and sensors aren’t exposed to high temperatures more than absolutely necessary, reducing the risk of tool failure due to temperature fatigue.”

MAC24™: New Technology Showcase 2019 Winner

Just last month, the MAC24™, which is the first in the ProMAC Series, was selected as a winner in the New Technology Showcase at LAGCOE 2019 in Louisiana. The new MAC24 incorporates innovations in metrology and manufacturing, greatly improving log data quality, accuracy and reliability when logging tubing and casing mineral deposition, corrosion, wear and mechanical deformation. Relying upon a modular constant current sensor design that Probe developed specifically for the ProMAC Series, the tool provides high-stability and accuracy over its full operating temperature range up to 175°C.

The MAC24 calibration process has also been dramatically reduced from days to a few hours.

Designed with the utmost attention to measurement quality, the tool has been proven through extensive engineering and field-testing. At recommended logging speeds of 30 ft per minute (9 meters per minute), MAC24 meets industry standards with a vertical resolution of 0.12” (3mm). Considering future super high-resolution requirements, the tool will also be capable of sampling at up to 100 frames per second achieving a vertical resolution of 0.06” (1.5mm) at current industry-accepted logging speeds.

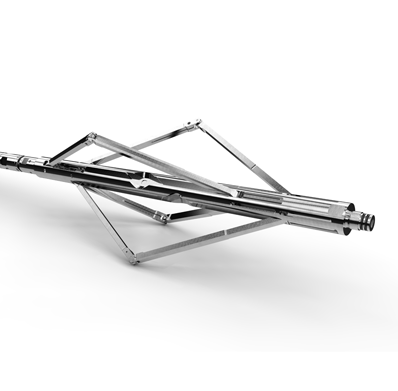

First XY caliper for geothermal well operations

In September, Probe introduced the UHT Dimension™ XY Caliper, the first XY Caliper Tool designed to operate in ultra-high temperature environments. The tool, which builds upon the Kuster® geothermal logging tool portfolio, performs in hostile environments up to 325°C (617°F) and provides two continuous independent perpendicular measurements (X and Y) of the internal diameter of the casing. It also generates a high-resolution temperature profile of the well via an external fast-response resistance temperature detector (RTD). It is the first caliper tool available to log in ultra-high temperature environments, such as those typically encountered in geothermal well operations.

Assessing well conditions increases efficiency of costly plug & abandonment operations

In other development news, Probe is hard at work on its Multi-String Isolation Logging (MSIL) tool, which offers a unique and cost-effective solution for assessing the isolation behind casing without pulling production tubing from the well. The aim is to provide operators with a ground-breaking technology to evaluate and determine cement bond quality and isolation without pulling the completion, thus greatly increasing the efficiencies and lowering the cost of plug and abandonment operations. By collaborating with a major operator, the tool is progressing on schedule, and has performed successfully in rigorous field trials in the North Sea. Probe plans to continue to collaborate further during 2020 with E&P operators in an extended field trial phase in order to fully prove the technology before going to market.